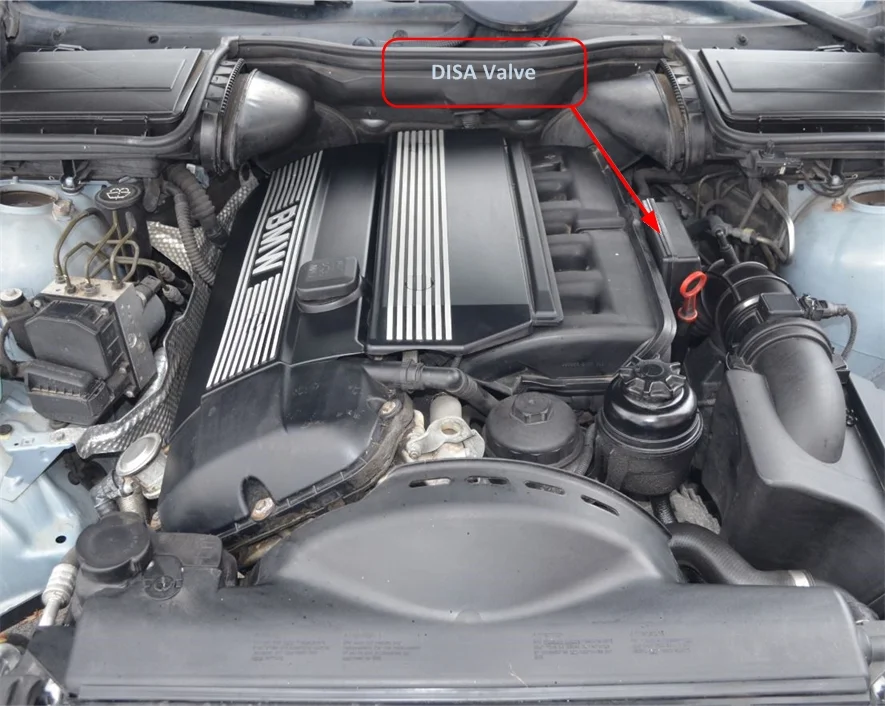

BMW engineers widely use a DISA (Differenzierte Sauganlage) system to change the intake manifold geometry. Thanks to this, the engines of the M52, M54, N42, N46, and other series combine good low-speed traction with high-speed power. DISA controls the airflow in the intake manifold, ensuring optimal cylinder filling at any speed.

As soon as the valve stops working, the engine loses responsiveness, torque drops, fuel consumption increases, and errors occur in the air control system. That is why regular inspection of the DISA and timely BMW DISA valve repair are key to the stable operation of the BMW engine.

How the DISA Valve Works

The principle of operation is quite simple, though the internal design is complex.

There are channels in the intake manifold of different lengths. At low speeds, the engine needs a longer channel to increase torque. At high speeds, a shorter one is used for better performance.

DISA is responsible for switching between long and short intake tracts; optimization of volumetric efficiency of the engine; smooth acceleration and stable traction throughout the entire rev range.

Control is carried out using a vacuum or an electric motor (depending on the generation). Inside the valve is a flap, an axis, and a drive mechanism – these are the parts that most often fail.

Common DISA Valve Failures

DISA is known for wearing out over time due to constant mechanical stress and high temperatures. Typical breakdowns are as follows:

- Broken or loose flaps. The plastic flap in older versions cracks, loses its rigidity, or breaks off completely.

- Worn shaft or bushings. The flap shaft develops excessive play, causing rattling, and the valve loses its accuracy.

- Air leakage through the seal. A damaged DISA ring causes uncontrolled airflow, disrupting mixture formation.

- Diagnostic errors. Often, fault codes related to intake runner control or airflow deviations appear.

If the problem is not addressed in time, debris from the flap can enter the intake directly and cause serious damage to the engine.

What a DISA Repair Kit Includes

The repair kit is designed to completely restore the mechanical part of the valve. It usually includes:

- A reinforced metal flap instead of a plastic one.

- A steel or aluminum shaft that minimizes backlash.

- Polymer or metal bushings that are wear-resistant.

- An O-ring that ensures tightness and prevents air leakage.

- Locks, pin screws, and other fasteners that ensure a reliable connection.

Such kits usually surpass factory plastic elements in strength and durability.

Step-by-Step DISA Valve Repair Guide

DISA repair is a job that is quite accessible even in a home garage. The main thing is to act carefully:

- Removing the DISA unit. Disconnect the connector, unscrew the fastener, and carefully pull the valve out of the intake.

- Initial assessment. Check whether the damper is loose, whether there is play on the axis, whether the seals are damaged, or whether there is extraneous noise.

- Disassembling the housing. Remove the old damper, pull out the axis, and dismantle the bushings. In parts are broken, remove any loose fragments.

- Surface cleaning. Use throttle body cleaner or carburetor cleaner. It is important not to scratch the seats.

- Installation of the repair kit parts. Install new bushings, a reinforced damper, and a shaft. Check the smoothness of movement – it should be completely smooth, with no sticking.

- Replacing the O-ring seal. A new rubber gasket will ensure tightness and eliminate air leakage.

- Assembly and installation back. Insert the repaired unit into the intake manifold and tighten the bolts with the recommended torque.

- Testing. Start the engine, listen to its operation, and check the throttle response. Instability, whistling, or rattling should disappear.

Performance Improvements After Repair

Restoring the DISA valve noticeably changes the engine’s behavior and returns it to the characteristics laid down by the manufacturer. After repair, the engine becomes more powerful at low RPM, especially during takeoff from a stop and driving in urban mode. The response to the gas pedal improves: the intake tract switches promptly, so the engine accelerates evenly without dips.

Correct mixture formation reduces fuel consumption, since the electronics are not forced to compensate for air suction or for incorrect flap operation. Idling also becomes more stable – vibrations, fluctuating idle speed, and extraneous noise disappear.

As a result, DISA repair restores optimal engine performance, improves fuel economy, and makes driving the car much more pleasant.

DISA is one of those BMW components that require attention but are easy to repair. A high-quality repair kit lets you eliminate wear, restore the integrity of the intake system, and restore its original performance. Timely diagnostics and proper assembly are a guarantee of stable operation of the intake system, efficient operation and protection of the engine from potential damage.

Regular monitoring of the DISA valve condition will help your BMW work as German engineers intended.