Mechanical Engineering Software

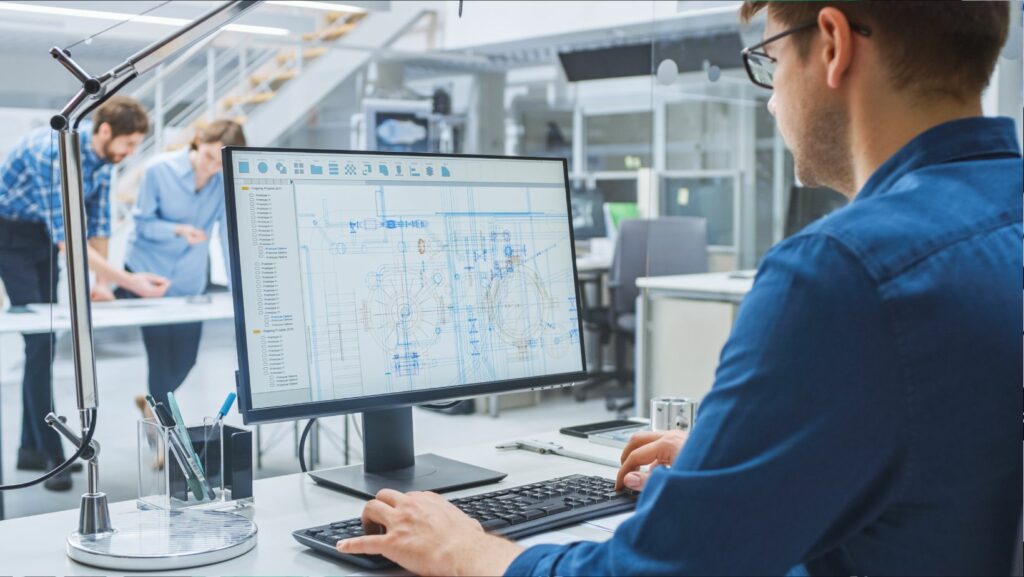

Mechanical engineering software plays a crucial role in the field by enabling precision, efficiency, and optimization of mechanical systems. Engineers rely on these tools to enhance design capabilities and streamline the engineering process, ultimately bringing their ideas to fruition and addressing complex design challenges in the industry.

Key Features and Tools

Mechanical engineering software offers a wide range of features and tools tailored to the specific needs of engineers as shown on venusautoperformance.ca. Some common functionalities include:

- CAD Modeling: Allows engineers to create detailed 2D and 3D models of mechanical components and systems.

- Simulation and Analysis: Enables virtual testing and analysis of designs for performance, durability, and other factors.

- Visualization: Provides realistic visualization of designs, aiding in communication and decision-making.

- Data Management: Organizes project data efficiently, ensuring easy access and collaboration among team members.

- Integration with Manufacturing Processes: Streamlines the transition from design to production, optimizing manufacturing processes.

- Automation: Automates repetitive tasks, saving time and reducing errors in the design process.

In modern engineering practices, mechanical engineering software is indispensable. It not only accelerates the design process but also enhances accuracy and innovation. Engineers can explore multiple design iterations swiftly, test complex systems virtually, and optimize designs for efficiency and cost-effectiveness. The integration of these software solutions in engineering workflows has revolutionized the industry, allowing for faster prototyping, reduced development cycles, and ultimately, more sustainable and inventive mechanical solutions.

Popular Mechanical Engineering Software

Mechanical engineering software plays a crucial role in the field by enabling precision, efficiency, and optimization of mechanical systems. These software solutions have evolved significantly with technology, offering innovative features that enhance design capabilities and streamline the engineering process. Let’s explore some popular options in the market that cater to the diverse needs of mechanical engineers.

CAD (Computer-Aided Design) software such as AutoCAD and SolidWorks are widely used in mechanical engineering for creating detailed 2D or 3D models of designs. These tools allow engineers to visualize and simulate their concepts, facilitating the development of complex components and structures with high accuracy. CAD software simplifies the design process, improves collaboration among team members, and accelerates product development cycles.

Finite Element Analysis (FEA) software like ANSYS and Abaqus enables engineers to perform complex simulations and analyses on mechanical designs. By applying mathematical models to predict how structures will behave under different conditions, FEA software helps optimize and validate product designs before physical prototyping. This advanced software aids in identifying potential weaknesses, enhancing product durability, and reducing the overall cost and time of product development.

Simulation and modeling tools like MATLAB and Simulink are essential for conducting virtual tests and experiments in mechanical engineering. These tools allow engineers to analyze and optimize various design parameters, predict performance outcomes, and refine designs iteratively. By simulating real-world scenarios, engineers can assess the functionality and efficiency of mechanical systems, leading to improved designs, reduced errors, and enhanced overall product performance.

Choosing the Right Software

When selecting mechanical engineering software, engineers must consider various factors to ensure the chosen tool aligns with their project requirements and budget constraints. Here are key aspects to evaluate:

Mechanical engineers should prioritize software that seamlessly integrates with their specific engineering projects. The chosen software should support the required design formats, simulation capabilities, and data management functionalities relevant to the project. By selecting software that aligns with the project’s technical demands, engineers can enhance efficiency and accuracy in their design and analysis processes.

Cost considerations play a crucial role in choosing the right mechanical engineering software. Engineers should evaluate the upfront costs, subscription fees, and additional expenses such as training and support services. Moreover, understanding the licensing terms and restrictions is essential to prevent any licensing conflicts or limitations that could hinder project progress. By carefully assessing the overall costs and licensing agreements, engineers can make informed decisions that balance functionality with budgetary constraints.