Precision is key in modern car making. The nano metrology system has changed quality control. It helps engineers find and stop tiny defects that could harm car safety and performance.

Car making has never been more precise, thanks to nanoscale tech. These systems let makers check parts at a molecular level. This way, they catch issues early, before they become big problems.

Real-time quality control is a big step forward in making cars. Unlike old methods that checked parts after they were made, nano metrology gives feedback right away. This cuts down on waste and makes cars more reliable.

This tech lets car engineers spot tiny changes that old tools can’t see. By finding small flaws, makers can make sure each part is just right. This means every car part meets exact standards with amazing accuracy.

From engine parts to electric car batteries, nano metrology is changing car making. These advanced tools are key to keeping cars safe, reliable, and top-notch.

The Evolution of Precision Measurement in Automotive Manufacturing

The automotive industry has seen a big change in how it measures things. Old tools like calipers and micrometers used to be the norm, giving measurements in millimeters. But as cars got more complex, the need for accuracy down to the nanometer level became key.

Coordinate measuring machines (CMMs) were a big step forward. They let makers get super close to the details of parts, with precision in micrometers. Now, parts like those in fuel systems need to be measured in just micrometers.

The nano metrology system is a huge leap in measurement tech. It can measure things 100,000 times smaller than a human hair. This is the level of precision needed for electric cars and self-driving tech to work right.

Now, car makers use super-accurate measurements to check parts, cut down on mistakes, and keep quality high. Moving from old ways to nano-precision has changed how cars are made and put together.

Understanding Nano Metrology System Technology

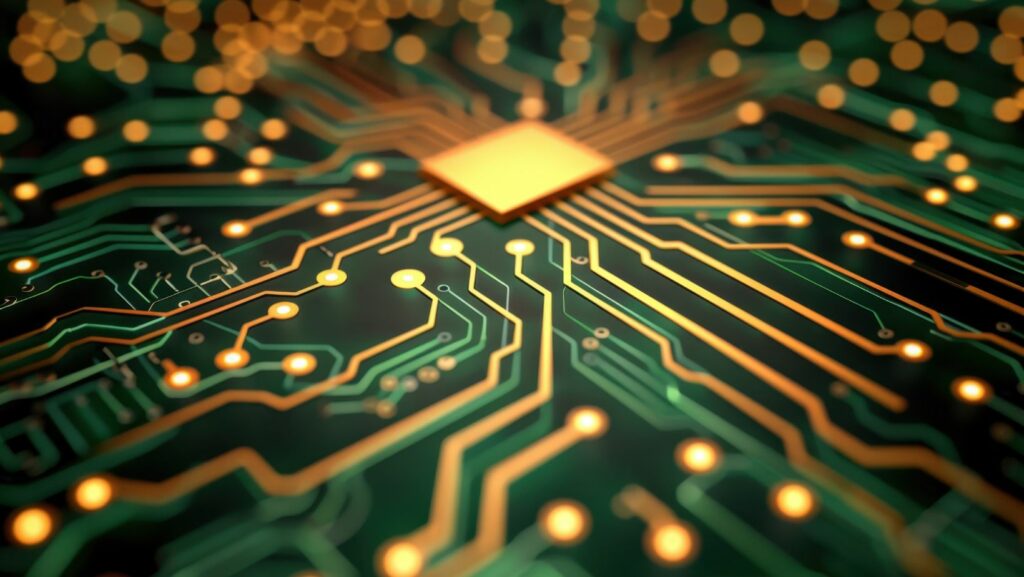

Nano metrology system technology is a new way to measure things in car making. It uses advanced tools to see tiny details with great accuracy. This lets makers check parts at the atomic level.

Atomic force microscopy is a key tool in this new tech. It lets engineers see surface details down to single atoms. Scanning electron microscopy adds to this by showing detailed images of surfaces, spotting flaws that others miss.

The parts of these systems work together well, using smart tech. They can handle lots of data fast, finding small changes that people might miss. This makes checking quality both precise and quick.

Today’s nano metrology systems are easy to use. They have simple interfaces that let workers check quality without needing to be experts. This makes using this tech a part of everyday car making.

Real-Time Quality Control: A Game-Changer for Automotive Production

The automotive industry is seeing a big change in quality control thanks to advanced nano metrology systems. Before, they used batch sampling and checked products after they were made. This often led to a lot of waste and finding defects late.

Now, real-time quality control is changing things. It lets manufacturers find and fix problems right away while they’re making products.

These systems use nano metrology to check products as they’re made. They track details with super accuracy. This means products can be fixed right away, making production much more efficient.

Statistical process control at the nanoscale is a huge step forward. It lets manufacturers spot tiny changes in how things are made. For example, they can see when tools need to be replaced, keeping quality high.

Putting nano metrology systems right on production lines is a big step forward. It helps make products more reliable, saves money, and gets them to market faster.

Critical Applications in Engine Component Manufacturing

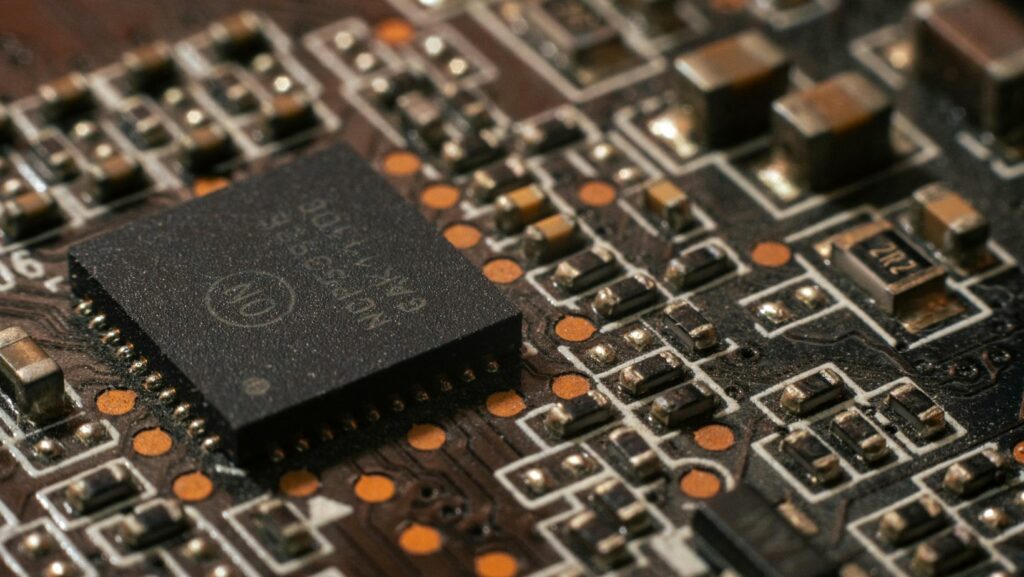

Precision is key in modern engine part making. Nano metrology systems have changed how we check quality. They help make parts that need to be very accurate.

Cylinder heads are very important for engine performance. Now, makers use advanced nano metrology to check them closely. Even tiny changes can affect how well the engine works.

Fuel injection needs to be just right. Nozzle holes must be the perfect size and shape. Nano metrology finds tiny differences that others might miss, making fuel use better.

Checking bearing surfaces is also crucial. Smooth surfaces mean less friction and longer engine life. Nano metrology spots small problems that could cause big issues later.

Using these new tools, car makers can make better engine parts. These parts are reliable, efficient, and last longer. Customers get engines that are better than they expected.

Enhancing Safety Through Advanced Surface Analysis

Automotive safety relies on checking materials at the smallest scales. Nano metrology systems have changed how we inspect for risks. They find defects that old methods miss.

Checking for tiny cracks is key to avoiding big failures. A small crack in a car part can grow and cause sudden failures. Testing material integrity helps find these weak spots early.

Car makers use nano metrology to check important parts like brakes and steering. They look at surfaces with great detail. This helps find small problems that could affect how a car drives and keeps drivers safe.

This tech does more than just look at things. It gives deep insights into materials. This helps engineers spot hidden weaknesses. It makes sure every part is safe, protecting people and the company’s image.

As cars get more complex, especially electric and self-driving ones, nano metrology is vital. It’s a key tool for keeping cars safe and reliable. It turns tiny details into big safety wins.

Reducing Production Costs with Immediate Defect Detection

Automotive makers are finding new ways to cut costs with advanced nano metrology systems. These systems spot defects right away, changing how quality checks are done. They find tiny flaws in real-time, cutting down on wasted time and materials.

The benefits of nano metrology systems are big. They catch problems early, saving parts and avoiding big rework costs. Old ways of checking quality often miss big issues until it’s too late, leading to big losses.

Another big plus is predictive maintenance. These systems watch tool health and warn when it’s time to replace them. This keeps machines running smoothly and cuts down on unexpected stops, making production better.

Looking at the numbers, it’s clear these systems pay off fast. Companies using them see quick returns. They save on repairs, labor, and make products that last longer, making it a smart choice.

Smart companies are moving from just fixing problems to preventing them. Nano metrology systems are a smart investment in making things better, faster, and more reliable.

Integration Challenges and Solutions in Automotive Assembly Lines

Adding nano metrology systems to car production lines is tough. It needs careful planning and special skills. Modern lines face big technical hurdles when they bring in new measurement tools.

Starting with the physical setup, nano systems need a very specific environment. This includes little vibration, exact temperature control, and super clean spaces. Often, factories have to change their areas to fit these tools.

Setting up these systems also means managing lots of data. They need to work with big software systems used in car making. Engineers must find ways to link old systems with new ones.

Teaching the team about these new tools is key. Workers need to understand how nano metrology works. Having experts inside the company helps everyone get on board.

Starting small with nano metrology is a smart move. Focusing on key parts first shows how it improves quality. This way, it doesn’t mess up the usual production too much.

The Impact on Electric Vehicle Battery Manufacturing

Nano metrology systems are changing electric vehicle manufacturing. They ensure battery production is precise. Traditional methods can’t match the needed microscopic quality control.

Battery performance depends on accurate electrode surface measurement. Small imperfections can cause hotspots or lower efficiency. Now, nano metrology systems can spot and fix these tiny issues.

EV production needs careful monitoring of battery parts. This includes separator membranes, electrode coatings, and tab welding. Any defect could be dangerous, making real-time checks crucial.

Battery quality control has become advanced with nano metrology systems. They measure coating thickness, check membrane uniformity, and verify bonding. This ensures each battery cell is safe and efficient.

The shift to electric vehicles in the automotive industry depends on these new technologies. Nano metrology systems make battery manufacturing safer and more precise, thanks to data-driven engineering.

Future Trends in Nanoscale Quality Control for Autonomous Vehicles

The future of making autonomous vehicles is changing fast. Advanced nano metrology systems are leading the way. They bring new levels of precision and smart monitoring to quality control.

Digital twin technology is a big leap in AI quality systems. It lets makers create virtual copies of their production. This way, they can test and improve their processes in real-time.

Artificial intelligence is key in quality control’s future. Machine learning can spot tiny issues that humans might miss. This means every part is checked to the highest standards.

New tech is making measurements better than ever. Systems can now check parts as they’re made. This is a big step forward, especially for complex parts in self-driving cars.

The mix of nano metrology, AI, and digital tech is changing car making. Sensors are getting smarter, and so is quality control. Soon, systems will not just measure but also predict and prevent problems.

Conclusion

The automotive industry is at a key moment. Nano metrology systems are now vital for staying ahead. These advanced tools improve quality control by offering unmatched precision in making things.

Car makers see how important tiny measurements are. They know how much they can change how a car works and lasts.

Car making is changing fast, thanks to nano metrology systems. They help check quality as cars are made. This is true for electric cars and traditional engines.

These systems give important details that help make cars better. They find problems early, saving money and making cars safer.

The future of car making will rely on advanced measurement tech. Big names like Tesla, BMW, and Ford are spending a lot on these systems. They want to make their cars better.

By using these tools, car makers can make their work better. They can cut down on waste and make cars that people want.

As car tech gets more complex, nano metrology systems will be key. Companies that focus on precise measurements will lead the way. The goal is to make cars smarter, safer, and more efficient.