Imagine pushing your body through 1,000 miles of rough terrain without rest, food, or water—how far do you think you’d make it? The same logic applies to heavy-duty trucks. These machines are built for endurance, but even they need regular care to perform efficiently and safely.

Whether you’re managing a fleet or running as an independent operator, understanding how often to service your heavy-duty truck isn’t just about following a manual—it’s about protecting your investment, your reputation, and the safety of everyone on the road.

Custom trucks, in particular, often require unique maintenance schedules because of specialized modifications and performance upgrades. From reinforced suspensions to advanced towing capabilities, these enhancements can affect how frequently parts need inspection or replacement. To explore examples of what goes into these builds, you can check this page for more details.

In this guide, we’ll explore how often you should service your heavy-duty truck, what factors influence those intervals, and how a smart maintenance routine can save you thousands in downtime and repairs.

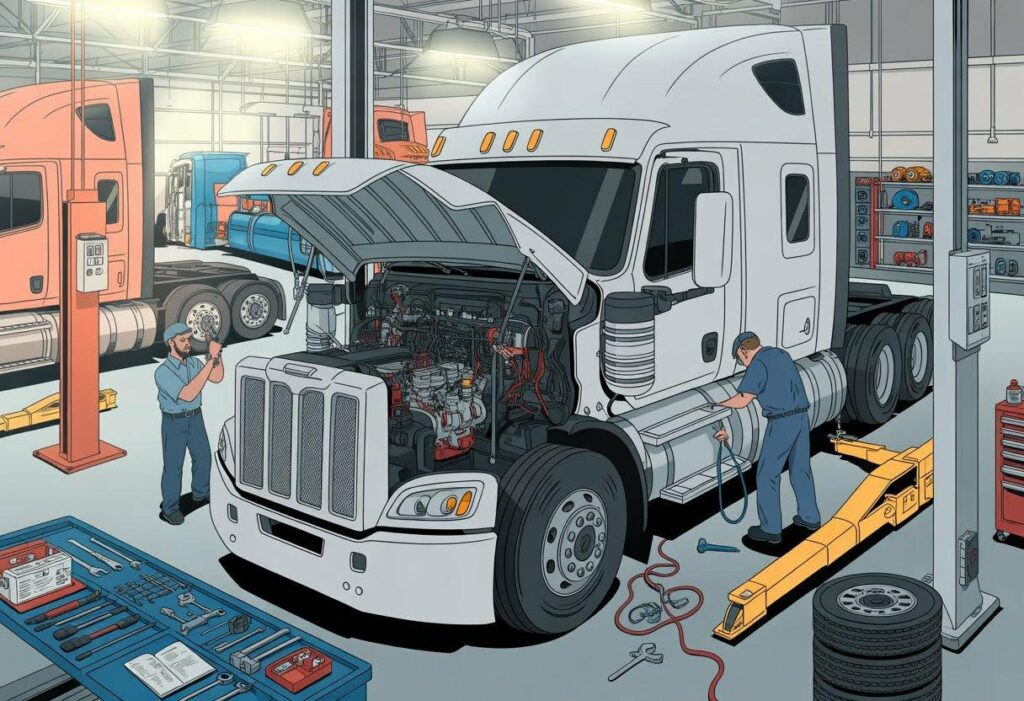

Why Routine Truck Maintenance Is Essential

Heavy-duty trucks log tens of thousands of miles every year, operating under extreme conditions. Over time, wear and tear is inevitable. Regular servicing ensures:

- Increased uptime – Minimize breakdowns and unexpected repairs

- Better fuel efficiency – Clean engines and well-maintained tires mean less fuel burned

- Extended vehicle lifespan – Proper maintenance can add years to your truck’s useful life

- DOT compliance – Avoid violations and out-of-service citations during inspections

- Enhanced safety – Working brakes, lights, and steering systems are non-negotiable on the highway

A well-maintained truck is more reliable, efficient, and cost-effective—period.

Factors That Affect Service Frequency

There’s no universal schedule that fits every truck. Here are key variables that influence how often you need service:

- Mileage Driven

The more miles you drive, the faster components wear down. Long-haul trucks require more frequent oil changes, filter replacements, and inspections.

- Truck Usage

Local delivery trucks with constant stop-and-go driving may wear out brakes and tires faster than long-distance trucks that cruise on highways.

- Load Weight and Terrain

Hauling heavy loads through mountainous terrain or rough roads adds strain on brakes, suspension, and the powertrain.

- Environmental Conditions

Extreme cold, heat, or exposure to road salt can accelerate corrosion, damage electrical systems, and affect performance.

- Manufacturer Recommendations

Always consider the OEM’s service interval suggestions. They provide a great baseline, but you’ll often need to adjust based on usage.

General Heavy-Duty Truck Maintenance Schedule

While every truck is different, here’s a common maintenance timeline that many professionals follow:

✅ Daily or Pre-Trip Inspections

Before hitting the road, drivers should check:

- Fluid levels (oil, coolant, brake, DEF)

- Tire pressure and tread wear

- Lights and signals

- Brakes and air lines

- Windshield and wipers

These quick checks can prevent major breakdowns and ensure DOT compliance.

🔁 Every 10,000–15,000 Miles

- Oil and filter change

- Lubricate chassis and driveline components

- Inspect steering and suspension

- Check belts and hoses

- Test batteries

This interval helps keep the engine clean and ensures smoother operation.

🔁 Every 30,000–50,000 Miles

- Replace air, fuel, and cabin filters

- Inspect and service transmission

- Check driveline and U-joints

- Examine brake system in detail

This is where deeper inspections can catch emerging problems.

🔁 Every 100,000+ Miles

- Full brake replacement (pads, rotors, calipers)

- Transmission and differential fluid change

- Cooling system flush

- Diesel Particulate Filter (DPF) cleaning or replacement

At this point, critical systems need attention to ensure your truck runs efficiently for the long haul.

Don’t Rely Solely on Mileage

Mileage is only one piece of the puzzle. Many trucks—especially those idling for long periods—wear down even when stationary.

For example, one hour of idling can equal 25 miles of engine wear. That’s why it’s smart to also track:

- Engine hours

- Fuel consumption

- Service history

Advanced fleet management software can help monitor these metrics and send automated reminders for servicing.

Fleet Servicing Best Practices

Managing multiple trucks? Here’s how to keep your entire fleet in top shape:

- Create a detailed preventive maintenance schedule based on each truck’s usage, mileage, and age.

- Stick with the same repair shop or technician to maintain consistent records and service quality.

- Use service logs or digital tracking tools to avoid missed maintenance tasks.

- Train drivers to perform pre- and post-trip inspections reliably and report issues early.

Partnering with trusted timber window companies in England or a qualified heavy-duty truck service center ensures expert diagnosis and consistent service.

Signs It’s Time to Service Your Truck (Even if It’s Early)

Sometimes your truck will tell you it needs attention—listen for the signs:

- Drop in fuel efficiency

- Engine misfires, hard starts, or rough idling

- Dashboard warning lights (Check Engine, ABS, etc.)

- Brake squealing or delay in stopping

- Unusual vibrations, pulling, or noise from under the hood

Ignoring these warning signs can lead to catastrophic failures and costly roadside repairs.

How a Trusted Repair Shop Can Help

Working with a professional heavy-duty truck repair shop gives you access to:

- Certified technicians who understand complex diesel systems

- Advanced diagnostic tools

- Custom maintenance schedules tailored to your routes and needs

- Timely DPF service, brake system checks, and component replacements

You’re not just paying for service—you’re investing in peace of mind.

Conclusion

There’s no one-size-fits-all answer to the question, “How often should you service a heavy-duty truck?” But one thing is clear: the more proactive you are, the more you save.

Routine service isn’t just about avoiding breakdowns—it’s about maximizing uptime, staying compliant, and extending the life of your investment. Whether you’re running one truck or a nationwide fleet, consistent maintenance will always be cheaper than unexpected repairs.

Need help building a custom service schedule for your truck or fleet? Contact our expert team today and keep your wheels turning—without the costly pit stops.