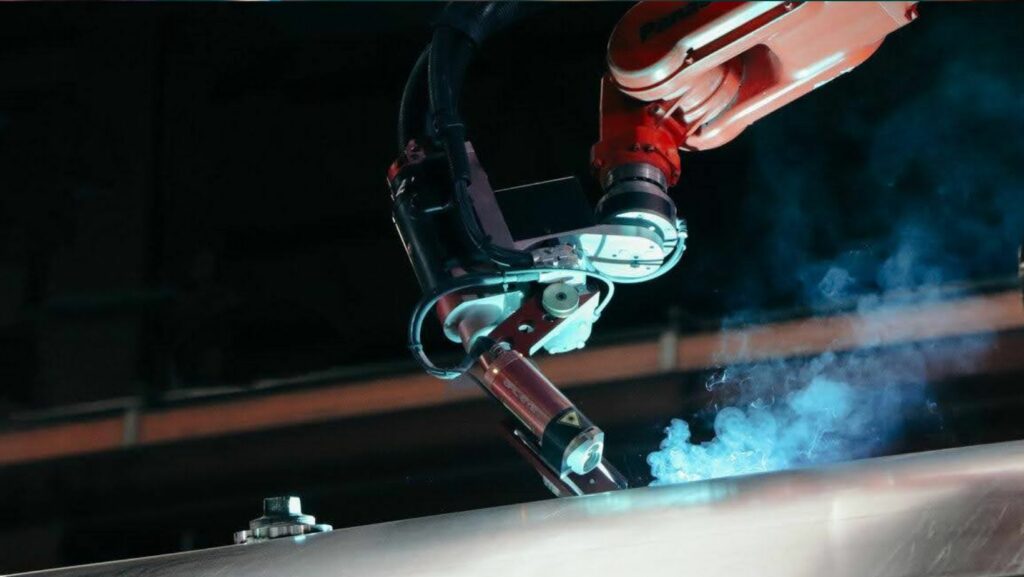

Welding was and always has been an art. It is demanding in terms of accuracy, patience and consistency, three aspects that are quite difficult to uphold hour after hour on a production floor that is busy with people.

Due to increased manufacturing requirements and the shortage of skilled labor, a high number of companies are resorting to robotic welders to stay afloat. The robot-arm by itself is however not the actual game-changer. It has the software which controls it.

Know that robot welding software is silently revolutionizing the way welding is carried out as the process is becoming quicker, safer and much more dependable. As much as the hardware might receive the highest attention, the software is what introduces the intelligent side, the flexibility, and the efficiency to the operation.

Consistency You Can Reliably Count On

Consistency is one of the largest problems of manual welding. Even very seasoned welders may give slightly varied results as they get tired or the circumstances vary. Robot welding software removes that variability by running the same programmed weld path each time.

After adjusting the parameters, which include speed of travel, length of arc, heat rate and position, the software makes sure that the settings do not change. The consequence is that the quality of welds is consistent throughout all parts, all shifts and all batches.

To manufacturers, this consistency would result in fewer defects, reduction in reworks and increased confidence that every finished product is up to specifications. Discover more here.

Quick Setups and Intelligent Programming

Recent robot welding software is not as user-unfriendly as it was before. Rather than writing complex code one line at a time, the operators may plan welds using visual interfaces, simulation, and offline programming and the robot never touches a part.

This saves a lot in time in setting up. Virtual testing of programs is possible, it can be adjusted in a matter of minutes, and deployed with minimum disruption to production. In case of a design modification, it can be possible to update a weld path in a matter of minutes rather than hours.

Enhanced Efficiency Without Exhausting Employees

Robot welding software enhances human efficiency rather than displacing it. Skilled workers save time and energy by not having to repeatedly weld. This frees them up to focus on more valuable activities like quality control, system oversight, or optimizing programming.

Thanks to the software, robots can operate nonstop for extended shifts without taking any rest. This does more than boost production; it also keeps it steady, https://www.thefabricator.com/. Timelines for production are more stable, targets are less difficult to achieve, and bottlenecks are less difficult to control.

Simultaneously, employees have reduced physical demands, which in turn leads to less weariness and less strain over time.

Increased Shop Floor Safety

Workplaces that include welding pose certain risks. An awkward position, high temperatures, sparks, or fumes can all lead to serious harm. By using robot welding software, workers can be safely removed from potentially dangerous regions while the operation is precisely controlled.

Robots can do repeated and risky welds, allowing people to stay safe while they keep an eye on systems. Controlled mobility, collision detection, and accident-reducing safety zones are all features made possible by the program. A safer workplace, reduced insurance premiums, and fewer injuries are the long-term results of this.

Auto-Tracking and Built-In Quality Control

Robot welding software produces data, which is one of its most underappreciated advantages. You can keep tabs on, record, and analyze every single weld. You may monitor arc stability, voltage, current, and travel speed in real time.

The welding process can be better understood with the use of these data. It is easier to determine what went wrong in the event of a problem. It is possible to make changes before issues become worse if performance begins to decline.

With this much light, welding becomes a proactive process rather than a reactive one. Manufacturers can avoid issues entirely rather than addressing them after the fact.

Cost Savings in the Long Run

The robot welding software might be a very expensive investment in the beginning, but it will prove worthwhile in the long run. There is a reduced scrap and rework with a consistent weld quality. Faster setups minimize downtime. It enhances throughput without necessarily increasing the labor hours because of the enhanced productivity.

The software optimizes the paths of the weld and the heat input, and thus, reduces the amount of waste. Less over-welding results in reduced filler material and distortions which require subsequent corrections.

These savings that will accumulate provide robot welding software not merely as a technological breakthrough; it is a cash-cow.

Easier to Scale Up With Addition of More Production

Numerous occasions, paperwork processes are not able to support the fast growth of a business. The production cannot always be scaled, and competent welders require time to be hired and trained. Robot welding software provides a scalable solution.

One can develop an optimized process and only move it to a large number of robots or assembly lines. Due to this fact, capacity expansion is not so cumbersome as new workflow, which has to be initiated.