Modern vehicles are becoming more advanced than ever, but many engines and transmissions still show early signs of wear or sudden failure. These problems are pushing makers to think more about how they design and test new productions. While the goal remains reliability, the route to achieving that is changing. Here is how the defects are reshaping new designs.

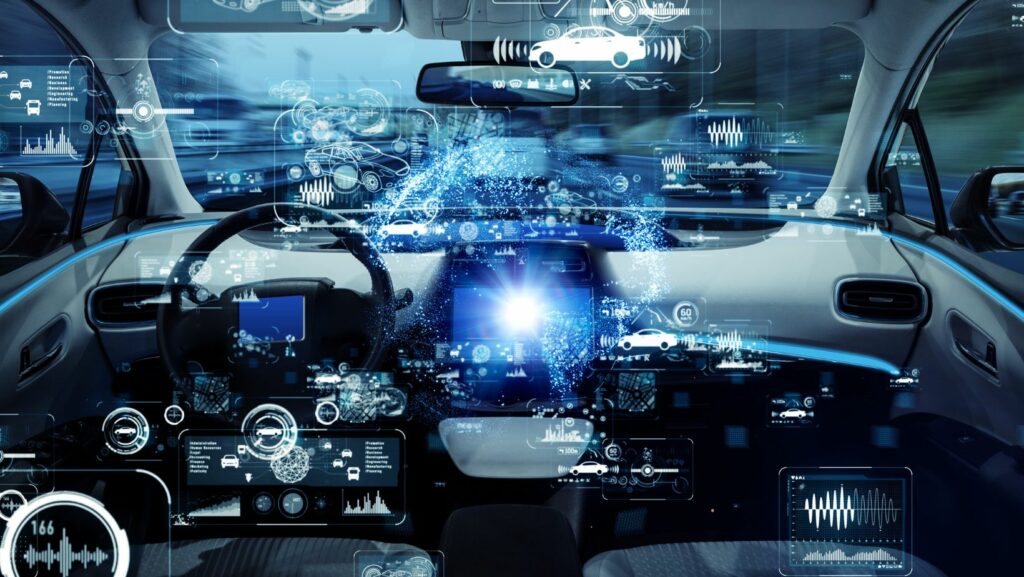

1. More Attention on Real-Time Monitoring and Predictive Diagnostics

Many engine and transmission issues start small and escalate quickly if not fixed. Signs like unusual noises, smells, and shifting delays may indicate problems with transmission. Meanwhile, faulty sensors and misfires may signal engine failures. Failing to fix these minor signs can kill the vehicle over time. Since monitoring these defects can be challenging, drivers now want advanced systems that provide early warning and improve reliability.

Automakers address this growing demand by building more real-time monitoring systems into engines and transmissions. Modern sensors can now track heat, vibration, fluid pressure, and shifting patterns. Engineers also use this data to spot patterns in weak patterns. Moreover, predictive diagnostics help collect and analyze data while the vehicle is on the road. These alerts give engineers a clear picture of how components behave, while allowing drivers to act before a breakdown.

2. Stronger Emphasis on Stress Testing and Quality Validation

Manufacturers once relied heavily on controlled quality testing environments. However, recent defects have proved that these tests rarely match real driving conditions. Current testing is becoming more rigorous and more honest. That means modern engines and transmissions pass through longer cycles, higher loads, and wider temperature swings. Automakers also use actual field trials to expose parts to daily traffic and climates rather than spending more time in labs.

The goal of this emphasis on quality validation is to find weak points early and fix them in subsequent productions. Automakers also study how materials age over time and how fluids react under constant heat. These details matter because many minor issues become difficult to fix after the vehicle has been sold. This allows manufacturers to reduce recalls and establish long-term reliability by improving how they test and validate each part. That is true as more consumers seek to use the GM buy back program for their defective vehicles.

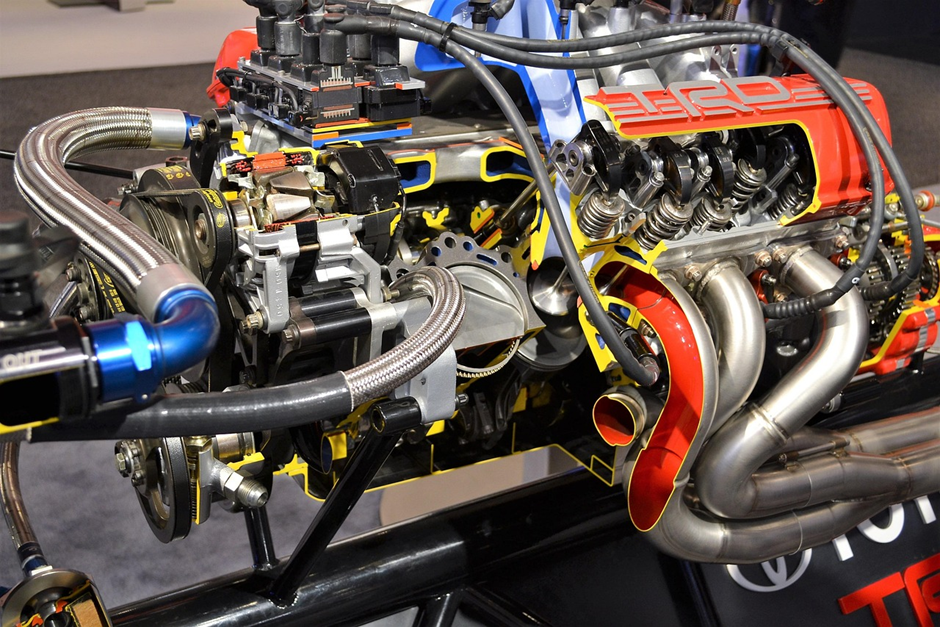

3. Re-Engineering Powertrains for Better Heat Management

Heat is one of the leading causes of engine and transmission failure, and with modern vehicles producing more power in compact spaces, heat builds up fast. Many recent car issues have also been linked to overheating, worn seals, and fluid breakdown. The trend has pushed manufacturers to rethink how they manage temperature inside the powertrain. This includes producing designs with larger cooling channels and improved airflow.

Today’s engineers use new materials that can handle higher temperatures for extended periods. Others are also changing how fluids flow through the system to cool and protect parts effectively. This helps engines and transmissions run smoothly and save on fuel. The area has become a priority in today’s automotive sector. As a result, future powertrains will likely handle stress better and avoid many failures.

Endnote

The exciting field of vehicle engineering is never stagnant, as innovations continue to address engine and transmission defects. Automakers are now improving on early detection and innovative heat control instead of fixing issues after they appear. These improvements may not be flashy, but they make a difference in the sector. That is particularly true as technology advances and consumers demand more reliable vehicles.